My first major project in the space, through this effort I came to understand the different technologies, sensors, and hardware involved in developing the kind of perception coverage we aimed to achieve for our autonomous vehicle.

The overall goal was to begin developing units with a more overall professional appearance and finish without compromising on performance and while maintaining optionality to grow the technology.

I was able to work alongside my colleagues in the Hardware Team to develop my concept fully in 3D, responsible for the entire process through releasing of final data for production of composite and plastic parts. I also was responsible for researching and vetting new potential vendor partners, developing cost and timeline estimates and ultimately final partner selection.

I was hands on with the vendor in tooling strategy and trouble shooting for both the composite and plastic cast parts. I made multiple site visits to inspect first articles, document areas of concern, and work solutions for revised mounting hardware, brackets, and part geometry.

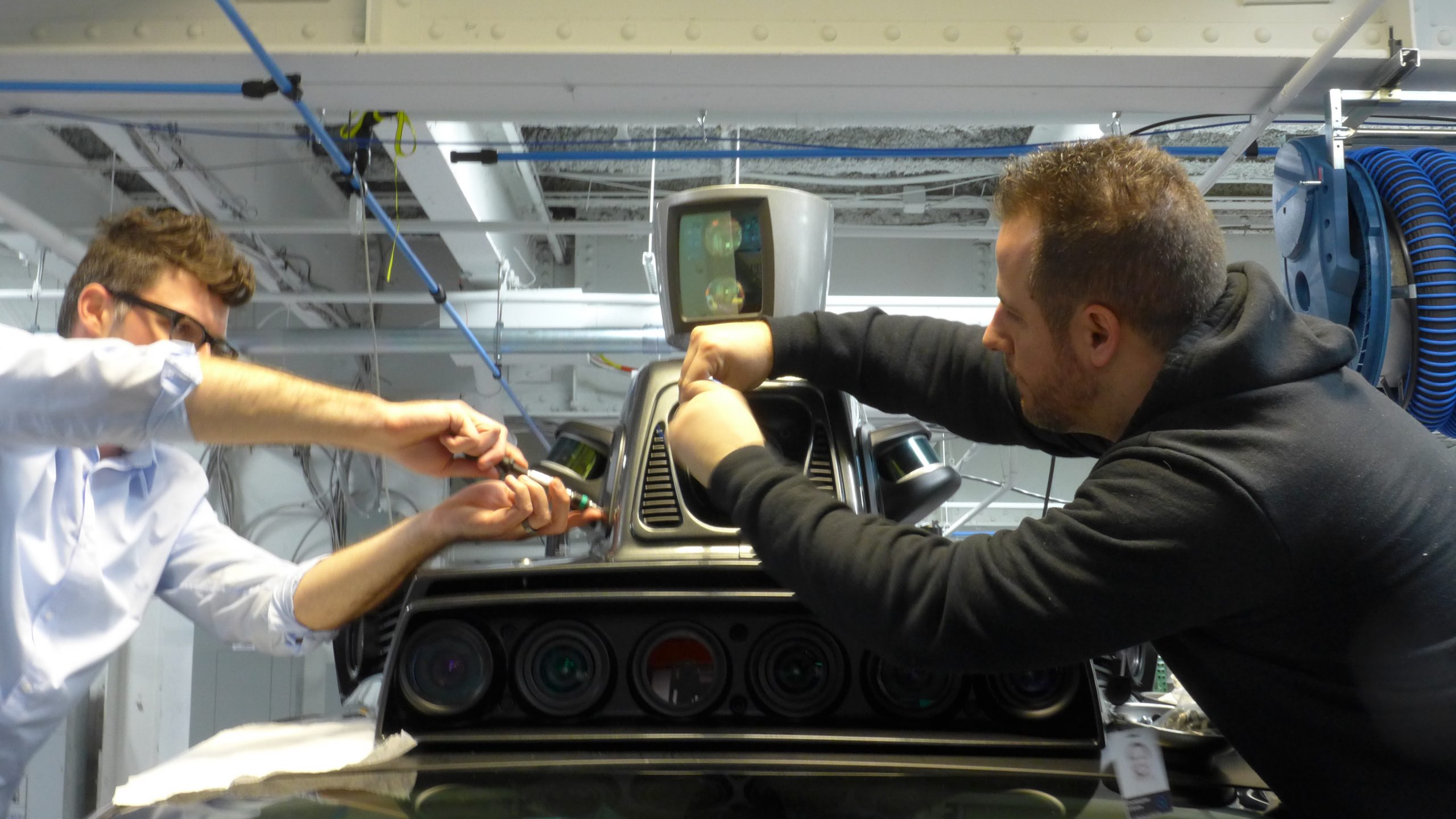

Once parts arrived in house, I had similar interactions with our Tech Team. I assembled and demonstrated the process for the team on a first article and continued to work through small modifications with them on subsequent builds as our internal hardware had continued to evolve as well even after design release.